Making a plastic profile is much more than just extrusion.

It is the result of a careful design process that allows you to optimize production and create a fully customized high-performance product.

VBN is a qualified partner, able to provide assistance in all development stages of design ideas up to the creation of the customized plastic profile.

The co-design of the plastic profiles

VBN has 65 years of experience in the extrusion of plastic materials and in the creation of customized solutions. Our company has a unique and highly specialized know-how in this sector. We are skilled in translating specific requests in best practices and study personalized responses for our clients. Everything stems from careful listening to your needs to transform your ideas or technical drawings into an operational project.

The feasibility analysis, the choice of plastic materials, the customized design, the elaboration and engineering of the plastic profile are carried out by the technical office in co-design with our clients.

VBN accompanies companies in all the steps to design and produce extruded plastic profiles, providing continuous consultancy and assistance.

Thanks to the interaction with our customers, it is possible to significantly reduce construction times and optimize project costs.

Custom design services

Our customer is accompanied through all the phases that lead to the realization of the product in plastic material.

Thanks to this working method it is possible to make the extrusion process and the subsequent production of profiles evolve in the right direction.

VBN’s design services include:

- custom co-design

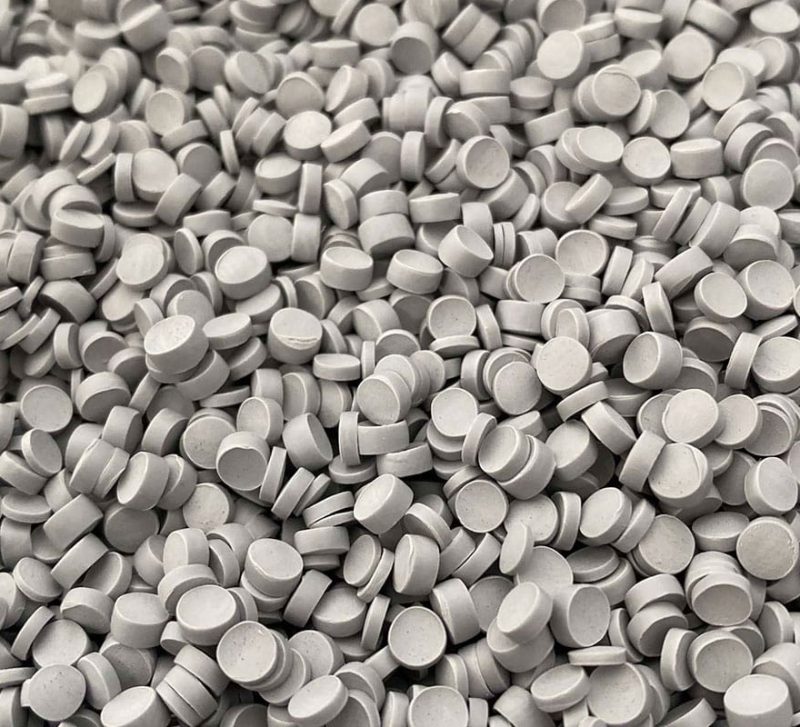

- materials consultancy

- rapid prototyping

- customized mold design

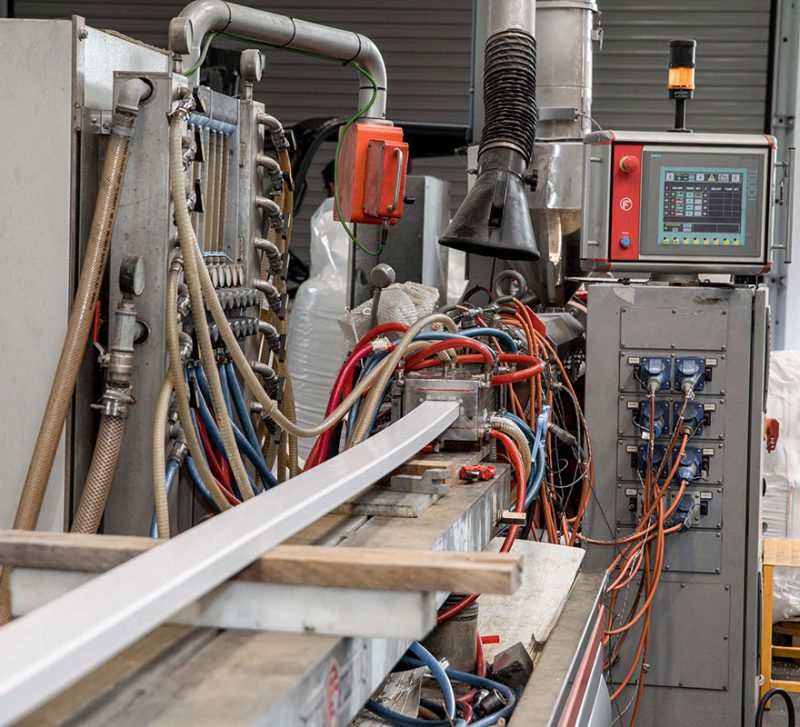

- production by extrusion or co-extrusion

- online and offline processing

- tests and checks.

Technological skills and knowledge of materials allow VBN to transform any idea into reality.

Thanks to the use of 50 different extruders and the ability to process many plastic materials, it is possible to carry out any project.