Profiles for industrial applications made from thermoplastic materials have many benefits linked to versatility, technical performance and production efficiency. These components are created by extrusion process and used in several fields, from construction and automotive to furniture and electronics. Our experience, know-how and knowledge of plastic materials allow us to develop customized designs and identify the most suitable solutions according to the required application.

The advantages of using profiles for industrial applications

The extrusion process of profiles for industrial applications allows for fast and efficient processing by conveniently adapting to production requirements. In addition, plastic polymers are significantly lighter than other materials such as metal, wood or stone. They can easily be used to manufacture products while reducing the overall weight without compromising strength. Many plastics used for extrusion offer excellent impact, tensile, and deformation resistance and also allow to create products that are resistant to chemicals, moisture and climate variations. Plastics are excellent insulators, making profiles for industrial applications suitable for electrical and electronic applications.

The fields of use of profiles for industrial applications

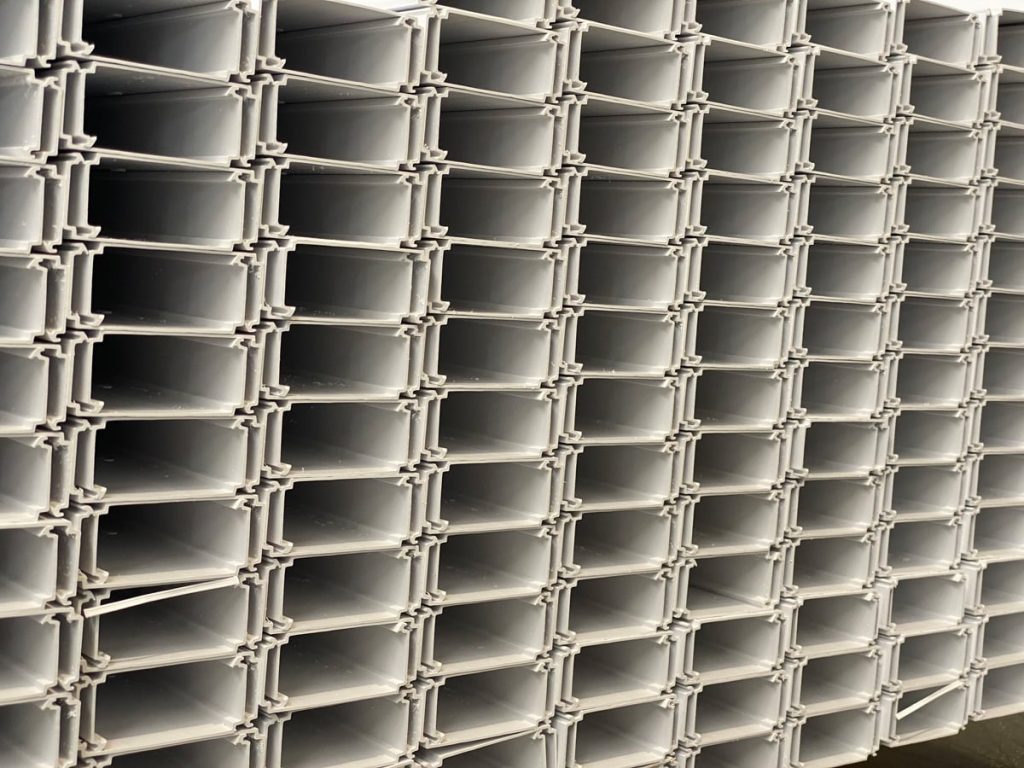

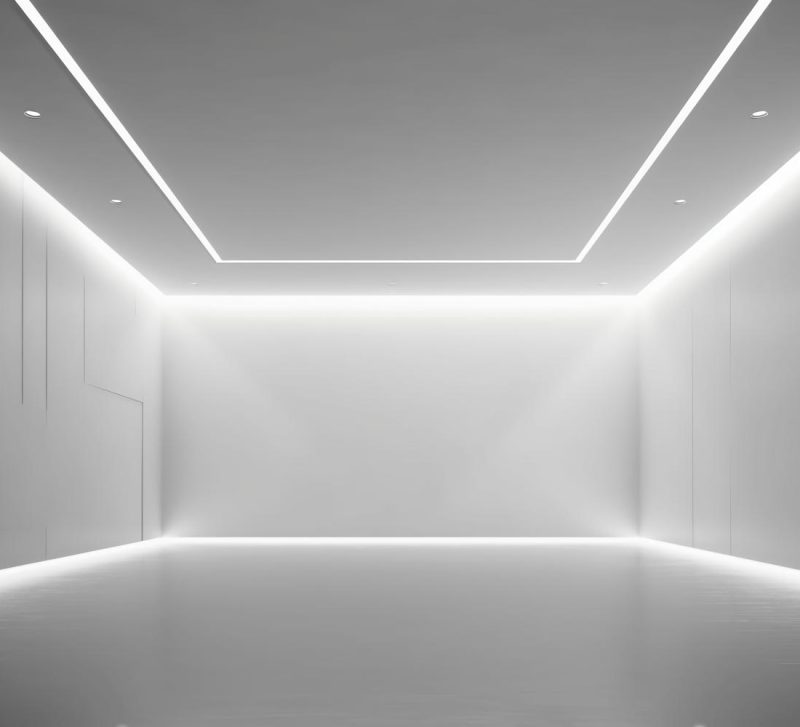

The uses of profiles for industrial applications are countless. Colors, shapes and sizes can be easily customized according to specific needs. Extruded products can be used in the construction industry to make profiles for windows, doors, wall coverings and structural components. In the furniture and design industry, plastic profiles can be used to create lightweight and strong structural components for furniture accessories, cabinets, desks, shelves and chairs, to make decorative frames and borders for doors and furniture, and to be built into lamps or lighting systems.

In the refrigeration field, extruded products allow to produce gaskets for refrigerators and freezers, shelves, drawers and internal compartments, condensed water drainage channels and door frame reinforcing elements. In the sports field, plastic profiles are ideal for creating equipment and structures for setting up sports facilities, such as soccer fields, tennis courts and ski slopes.

VBN is the partner to develop profiles for industrial applications

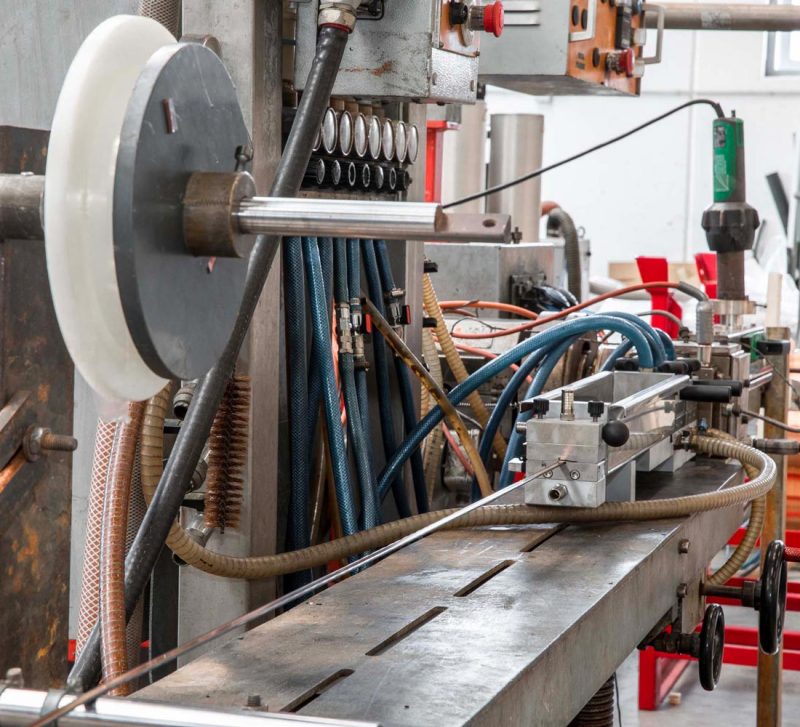

VBN has 50 extrusion systems that allow to produce profiles for industrial applications of all lengths, with cuts performed on customer’s request. This range of technological equipment offers a wide range of solutions in profile extrusion by size, screw-barrel combination, hourly productivity, kind of puller and cutter assembly.

In the production of profiles for industrial applications, VBN can adopt both single-screw and twin-screw extruders, formed by 2 parallel or conical interlocking screws that rotate within the cylinder. This solution allows to produce more complex and heavier extrusions and to extrude different materials simultaneously.

Check out what industries VBN’S profiles for industrial applications are used in.