PRODUCTIVE PROCESS

Plastic processing and production of extruded profiles

We provide a complete service to manufacture finished products by extrusion and co-extrusion of plastics.

We accompany customers with a turnkey service to make finished products in different types of plastic materials: from mold design to finishing processes that complete the extrusion process. 50 extrusion systems equipped with the latest technologies, integrated into the production lines, allow each project to be shaped.

Our production process

We guarantee control and quality at every step of the production process.

All processing is carried out in-house

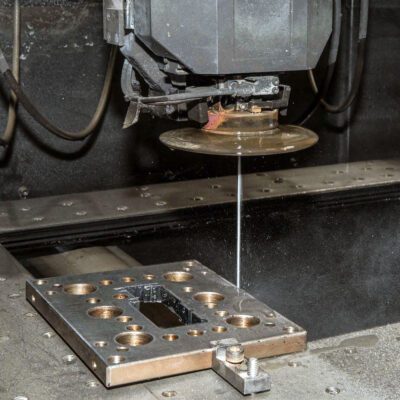

In the company’s in-house workshop department we make custom moulds for each project to be used in the mass production of profiles and tubes in different types of plastic materials.

Modern CAD-CAM and CNC technologies allow you to perform fast and precise processing of any size and design.

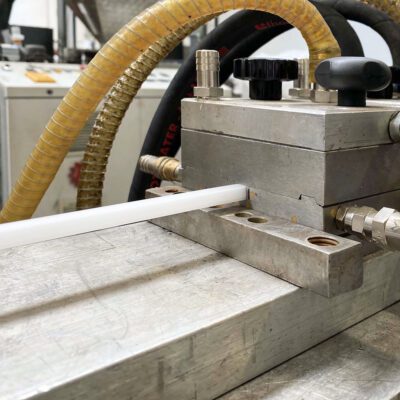

Profile extrusion is carried out with modern high-performance technologies. The possibility of choosing from 50 extruders with different characteristics offers the extraordinary ability to develop a virtually infinite range of products.

Co-extrusion represents an available technology through which with a single extrusion it is possible to combine two or three plastic materials having different degrees of rigidity.

The finished product is achieved through a single process. Thanks to the use of automatic machinery and cutting-edge profile extrusion technologies many processes are placed directly within the production lines.

After the extrusion process, the profile is completed with different types of processing such as custom cutting, drilling, punching, CNC milling, and assembly.

Our working method is based on specialised expertise developed over 60 years of experience and the use of 50 different plastic extrusion systems.

Each stage of the extrusion process is carefully designed. The development of customised moulds according to customer requirements, the selection of the best performing plastics, the choice of the most suitable extrusion systems, and the engineering of production system are fine-tuned with utmost care. The whole production cycle takes place in-house with the highest quality control.

CUSTOM

Custom extruded profiles and tubes

From custom mold to the profile: 50 extrusion systems and innovative plastics processing are at the service of our customers.

We shape tailor-made projects thanks to a consolidated know-how on materials and polymers, mold design, design and final processing of plastic.